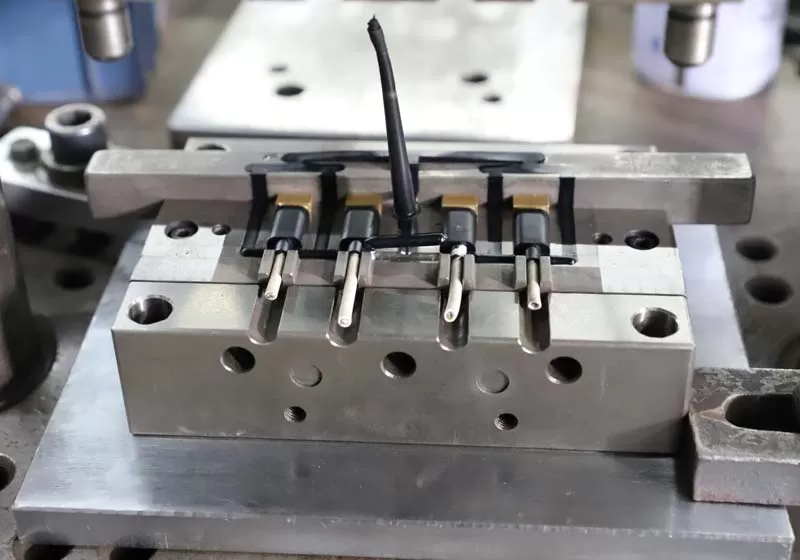

Introduction: Android Data Transfer Cable Plastic Injection Mold Die

Type-C Automatic mold / android plastic injection mold die

It’s one mold with four products. The usage count more than 300,000 times to product manufacturing. The mold makes by Material SKD11 or D2, HRC58-62. And this is one mold with four products so 300,000 times will be make 1,200,000 products. Of course, if you regular maintenance the mold, the mold can be used more than 300,000 times.

Using high-quality SKD11 steel (you can also change to a good DC53 material if you have special requirements), durable, properly maintained, and the life span can reach more than 300,000 molds.

The daily maintenance of the mold by the operators during production has a great influence on the durability of the mold.

Length: 210 MM | Material: SKD11/D2 |

Width: 160 MM | Usage count: 300,000 |

Height: 110 MM | Machine equipment: Vertical |

Weight: 25 KG | Mold Type: Automatic |

Maintenance During Mold Installation

1. Clean the upper and lower surfaces of the mold before installing the mold to ensure that the mold mounting surface and the press table are not crushed and the parallelism of the upper and lower mounting surfaces of the mold during production;

2. After the mold is installed, open the mold and clean all parts of the mold, especially the guide mechanism. For the surface mold, the odd-shaped surface must be cleaned to ensure the quality of the part;

3. Lubricate each sliding part of the mold and apply grease;

4. Inspection of all parts of the mold, especially safety parts. Such as: safety side pins, safety screws, side guards, punching waste channels, etc.