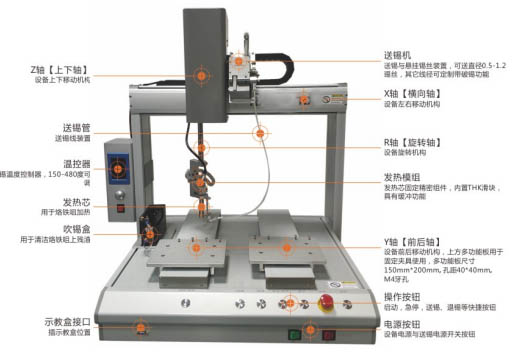

Introduction:Desktop Soldering Machine, flexible and diverse soldering methods, with functions such as spot welding, drag welding (pull welding).

Desktop Soldering Machine

Flexible and diverse soldering methods, with functions such as spot welding, drag welding (pull welding).

Aluminum profiles are molded and cast, no deformation, no rust, and stable operation.

Programming supports point-to-point, block-to-block copy arrays to reduce programming time.

Each motion axis adopts Lesai closed-loop motor to improve equipment reliability and lifespan.

Equipped with automatic cleaning function to improve product quality and soldering iron tip life.

The welding module has a buffer function to effectively reduce product damage.

Temperature range 150-480C, display real-time power consumption, PID algorithm and frequency conversion technology.

With tin breaking function, it can effectively reduce tin slag splash and improve product quality.

Supports the configuration of smoke purifier to solve the problem of solder smoke.

Supports the installation of preheating devices to solve soldering problems for large metal products.

| Project | Parameter | Four-axis soldering machine 331R | Dual Y-axis single-head welding machine 5331R | Double-head automatic switching soldering machine 5331D | Double-head automatic switching soldering machine 5331R-2Q | Three-way automatic soldering machine 5331R-35 | Four-head automatic soldering machine 5331R-4 | ||||||

| Itinerary (other itineraries can be customized) | X-axis | 300mm | Repeat accuracy ±0.02mm | 500mm | Repeat accuracy ±0.02mm | 500mm | Repeat accuracy ±0.02mm | 500mm | Repeat accuracy ±0.02mm | 500mm | Repeat accuracy ±0.02mm | 500mm | Repeat accuracy ±0.02mm |

| Y1-axis | 300mm | 300mm | 300mm | 300mm | 300mm | 300mm | |||||||

| Y2-axis | / | 300mm | 300mm | 300mm | 300mm | 300mm | |||||||

| Z-axis | 100mm | 100mm | 100mm | 100mm | 100mm | 100mm | |||||||

| R-axis | 360° | 360° | 360° | 360° | 360° | 360° | |||||||

| Load | workload | 5kg | |||||||||||

| XYZ | 3kg | ||||||||||||

| Drive mode | Timing belt + guide rail (optional screw rod + guide rail) | ||||||||||||

| Motor | Form/Power | 57 closed-loop motor (optional 400W same-service motor) | |||||||||||

| Drive | Closed-loop drive (optional 400W simultaneous server drive) | ||||||||||||

| Power supply | AC 220V/50Hz | ||||||||||||

| Rated power | Max_350W | ||||||||||||

| Driving power | Voltage | 24V DC | |||||||||||

| Electric current | Max.3.5A/Axis | ||||||||||||

| Temperature control type | Optional Wilo 200W, 150W, high power 600W and other temperature controls | ||||||||||||

| Heater | 400W (high power) [optional Wilo 200W, 150W, high power 600W and other heating cores] | ||||||||||||

| Wire supply method | 0.5-1.2mmm (With broken tin, other wire diameters can be customized) | ||||||||||||

| Machine dimension | 620*600790mm | 820*600*820mm | 920*600*820mm | 920*600*820mm | 820*600*820mm | 980*600*820mm | |||||||

| Machine weight | 45Kg | 65Kg | 70kg | 70kg | 72kg | 75kg | |||||||

| Four-axis soldering machine | ||||

| The four-axis automatic soldering machine adds a heating module rotation axis [R-axis] part on the basis of the three-axis automatic soldering machine. It can basically achieve welding without dead corners and is suitable for spot welding and drag welding on the same plane, such as PCB, frequency converter, etc. It can basically achieve welding without dead corners and is suitable for spot welding and drag welding on the same plane, such as PCB, frequency converter, etc. | |||||

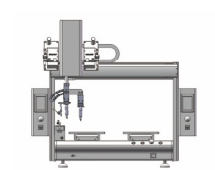

| Double Y single head soldering machine | ||||

| The double Y-axis single-head automatic soldering machine adds a Y-axis and dual working platforms to the four-axis automatic soldering machine, which saves the time of replacing fixtures, avoids the situation of machines and others, and further improves product efficiency. | |||||

| Double Y double head soldering machine | ||||

| The dual Y-axis double-head rotary soldering machine adds a welding module, dual working platforms, and dual heating modules to the dual Y-axis automatic soldering machine. It saves the time of replacing fixtures and at the same time double-head welding. In addition to the single-head equipment Basically, the efficiency is further improved. | |||||

| Double head automatic switching soldering machine | ||||

| The double-head automatic switching soldering machine adopts automatic switching mode, which can realize products with different sizes of solder joints in one machine. Use a large soldering iron tip to solder larger spots, and use a small soldering tip to solder small spots. Automatic switching can better meet the customer's personality for the product's needs. Can be equipped with 150W, 200W, 400W, 600W power soldering components | |||||

| Three-way tin automatic soldering machine | ||||

| The three-send automatic soldering machine can be used to solder three pins of the same component, which not only solves the problem of too small spacing. Can be equipped with 150W, 200W, 400W, 600W power soldering components. | |||||

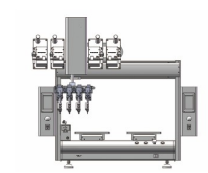

| Four-head automatic soldering machine | ||||

| The four-head automatic soldering machine can solder four points on the same product or the corresponding soldering points of the same four products at one time,which greatly improves the production efficiency of the product while ensuring quality. Can be equipped with 150W, 200W, 400W, 600W power soldering components. | |||||