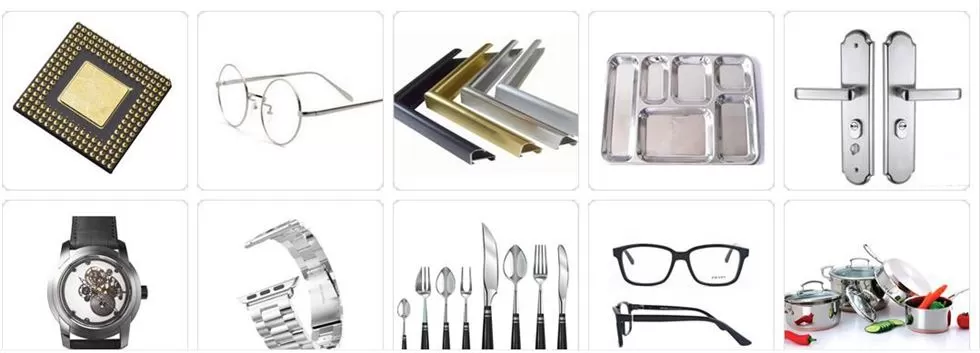

Introduction:The four column hydraulic press machine mainly was applied to pressing and forming of watch & clock parts, spectacle parts, tableware, photo frame, metal ornaments, lock parts and hardware etc.

Four Column Hydraulic Press Machine Application

The four column hydraulic push mainly was put on pressing and developing of a watch and clock parts, vision parts, tableware, photograph frame, metal decorations, lock parts plus hardware, etc.

Main Features of 4 Column Hydraulic Press

1). Energy saving in addition to emission reduction: Hydraulic and electronic handle adopt an intelligent servo-saving system, saving 50-70%

2). Safety & Accurate: Each machine is usually equipped with a great infrared safety grating, which effectively shields the safety of the operator. Typically the servo intelligent copyrighted control system assures that the machine’s repeat position reliability is up to be able to ± 0. 03mm and the strain precision is ± 1 bar.

3). Low failure level: Servo intelligent obvious control system, tend not to useless work, typically the oil temperature will not be easy to increase, in addition to there is zero negative pressure inside the oil system, a better reduction of disappointment, prolong the life span of hydraulic elements, electrical appliances together with automatic fault burglar alarm function and one-button reset function.

4). Stable & Tough: The frame switches into the frame construction of the complete machine, and typically the slider adopts accurate guide rails to be able to run. It is usually immune to shock in addition to side pressure, in addition to the whole equipment is stable, accurate, and durable. It truly is suitable for blanking, forming, extrusion in addition to other processes makes use of.

5). Ease of maintenance: Typically the whole 100 great deal four columns hydraulic press machine based on numerous functional modes, created into a flip structure, easy disassembly, a general fault could be viewed immediately through the feel screen, ease of maintenance.

Four Column Hydraulic Press Machine Technical Parameters

Model | Units | Specifications | ||||||||

YT-100X | YT-15X0 | YT-200X | YT-300X | YT-500X | YT-1000X | YT-1500X | YT-2000X | |||

Main cylinder capacity | ton | 100 | 150 | 200 | 300 | 500 | 1000 | 1500 | 2000 | |

System pressure(Max) | Mpa | 20 | 22 | 22 | 24 | 25 | 25 | 25 | 25 | |

Main cylinder stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 160 | 160 | |

Open height | mm | 380 | 350 | 400 | 400 | 450 | 600 | 650 | 700 | |

Approaching speed of working table | mm/s | 180 | 180 | 135 | 135 | 100 | 90 | 90 | 80 | |

Return rate table | mm/s | 150 | 150 | 100 | 100 | 90 | 80 | 80 | 75 | |

Sizes of working table | (L-R) | mm | 400 | 450 | 450 | 550 | 650 | 900 | 1100 | 1350 |

(F-B) | mm | 410 | 480 | 550 | 650 | 750 | 950 | 1100 | 1350 | |

Overall dimension | (L-R) | mm | 1140 | 1200 | 1320 | 1460 | 1630 | 2450 | 1680 | 2400 |

(F-B) | mm | 980 | 1140 | 1340 | 1340 | 1510 | 1700 | 1400 | 2600 | |

(H) | mm | 1400 | 1540 | 1630 | 1725 | 1990 | 2670 | 3100 | 3300 | |

Motor Power | kw | 4 | 5.5 | 5.5 | 7.5 | 15 | 18.5 | 22 | 30 | |

Weight (reference) | kg | 2200 | 2650 | 2800 | 3800 | 5800 | 9500 | 23000 | 35000 | |