pipe processing enterprises.

It can optimize your manufacturing process in several ways. In a single operation you can create perforations and complex contours. In addition, tubes can be cut into sections. This enables innovative design solutions that minimize downstream tasks such as deburring, welding, and assembly. The resources required for intermediate stages such as storage and part handing are also much lower, as a result you can steep up your process and significantly reduce costs per part over production methods that use conventional tools for sawing, drilling and milling.

Advantages:

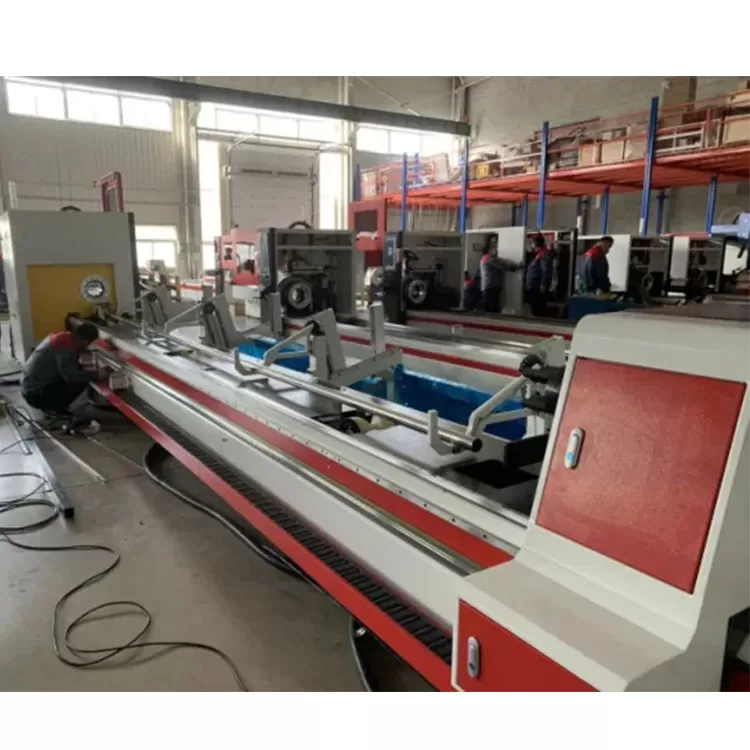

1. Feeding: Realize the intelligent material separation, feeding and seamless docking with the fiber laser

cutting machine after the whole bundles of tubes are placed in the feeding device, and ensure

that only one tube is delivered to the conveying arm each time.

2. Unloading: The finished product is automatically dropped to the storage bin, double support-bearing auxiliary support overlong tubes.

3. Automatically prepare while processing time to shorten feeding time.

4. Save labor and improve the production efficiency of the whole machine.

5. Automatically unload, separate of finished product from waste.

6. Reduce sorting and improve efficiency