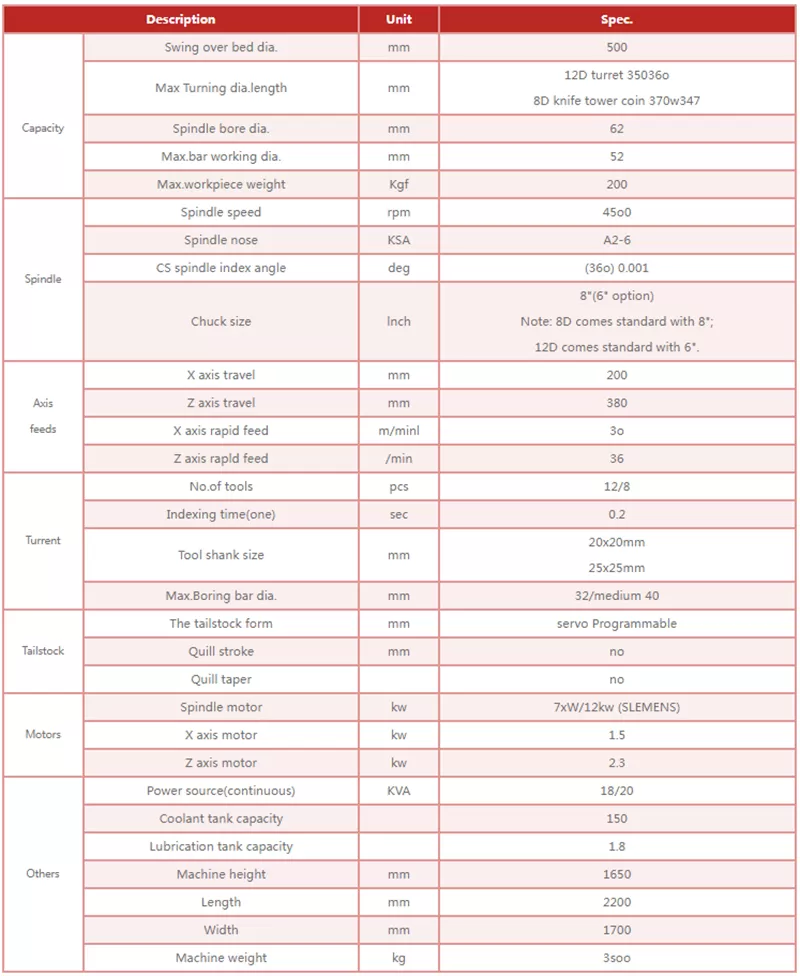

Introduction:HQT series horizontal CNC lathe HQT08-380

The high rigidity and precision spindle design can easily achieve strong heavy cutting

High rigid turret with accurate indexing

High quality drive components achieve optimal dynamic characteristics

High rigidity structure, minimum floor area

World leading Siemens CNC system

High quality closely baked cast iron castings

1. Automatic tool setting instrument: for the operator, it is only necessary to operate the Menu key or M program code in the NC system to automatically compensate the tool data to the NC system;

2. Programmable tailstock: suitable for bars of different lengths, with stable accuracy, strong operability, simplicity and flexibility, and superior rigidity;

3. Automatic workpiece collector: Automatically transfers the finished workpiece to the outside of the machine tool without opening the front door, improving processing efficiency;

4. Bar conveyor: Equipped with bar conveyor function, it can achieve automatic feeding and long-term unmanned operation;

5. Oil mist collector: absorbs and processes oil mist like coolant and oils, maintains a good workshop environment, ensures employee health, and extends the service life of the power system;

6. Oil water separator: separate the waste oil from Cutting fluid, extend the service life of Cutting fluid, save costs and protect the environment;

7. High pressure cooling device: can improve processing efficiency, extend tool service life, and achieve high-speed chip breaking function of copper and stainless steel materials. Different specifications of cooling pumps can be selected;

8. Online measurement device for workpieces: By setting a contact sensor, the accuracy of the processed workpiece can be automatically calculated, and tool compensation can be performed to ensure continuous machining stability.