Introduction:Fuel cell hydrogen energy film electrode automatic alignment screen laminating machine industrial equipment

Product Description

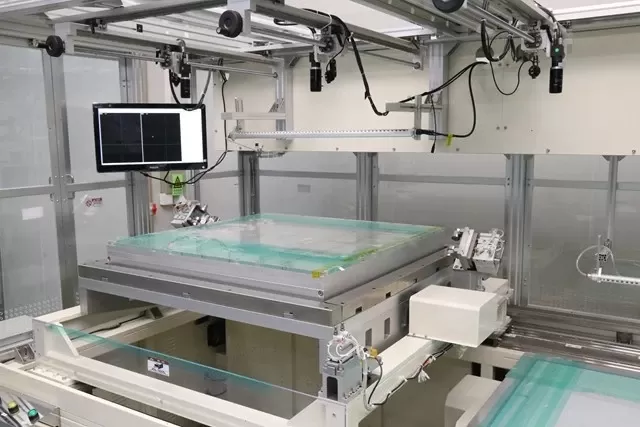

Fuel cell hydrogen energy film electrode automatic alignment screen laminating machine is a high-tech device . It has a

high-precision CCD vision automatic alignment platform system and a precise grid layout roller lamination system. The bonding technology of various film electrode materials, proton film, catalytic layer and border film is developed, which fundamentally eliminates the bubbles generated during bonding and anti-gravity vacuum unit, so as to prevent functional defects such as stretching and indentation of the film in the bonding process. Rigid/flexible laminate between various functional films and rigid/flexible lamination between various functional films.

No. | Item | specification and parameter | Quantity or requirement | Remark |

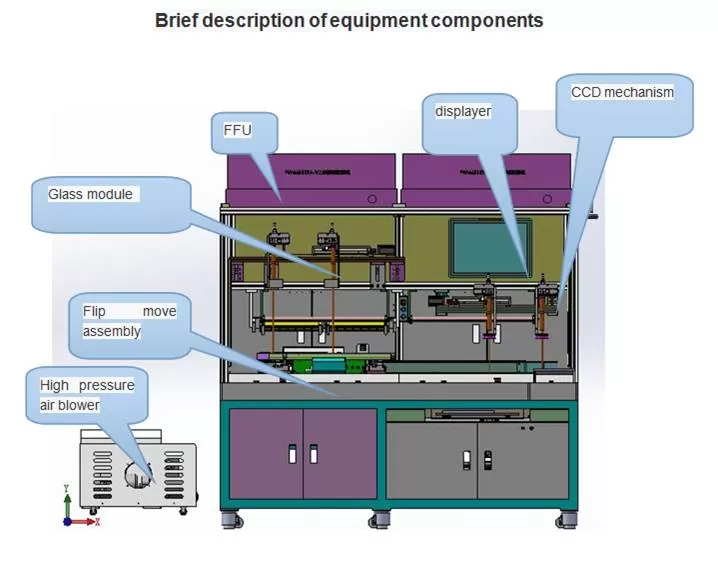

2.1.1 | frame | 2000*1270*2100mm L*W*H | 1ea | |

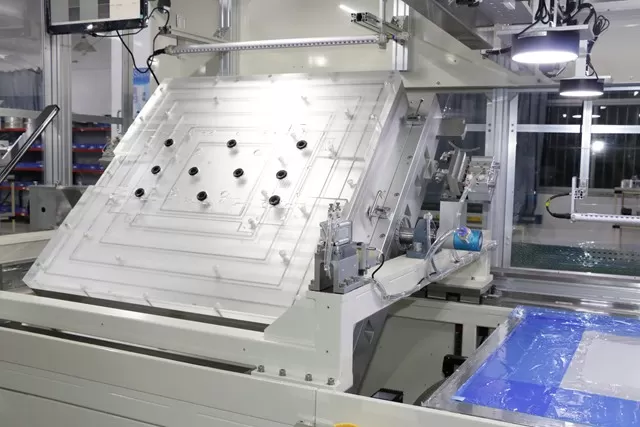

2.1.2 | Flip structure | 650*500mm | 1 set | Customizable |

2.1.3 | Anti - fall device for flip structure | Equipped with a brake system | 1 set | |

2.1.4 | lamination unit | Silicone roller | 1 set | |

2.1.5 | Clamping device | Cylinder (or electromagnet) | 1 set | |

2.1.6 | Adsorption unit | Vacuum generator | 2 sets | |

2.1.7 | CCD alignment system | Intelligent camera system | 1 set | |

2.1.8 | operation interface | 1 PC + displayer | 1 set |

No. | Item | specification and parameter | Remark |

2.2.1 | stage size | 640*480mm | |

2.2.2 | product size | 13 to 26 inches | POL |

2.2.3 | Stage operation mode | X、Y、θ Automatic Angle adjustment |

No. | Item | specification and parameter | Remark |

3.1.1 | capacity(C/T:cycle time) | 25~30ses/1pce, production at 20hrs/dCy: about 1200pcs/day operation time ≥98% | Manual loading and unloading is not included |

3.1.2 | failure rate | ≤2% | |

3.1.3 | Yield | ≥99% | NG incoming materials are not included |

No. | Item | specification and parameter | Remark |

3.2.1 | Parameter setting | Can be set on the screen and display parameters, such as: attach speed, length; | |

3.2.2 | Password lock | There are three password functions, namely: supplier, engineer and operator | When modifying parameters |