Introduction:Dehumidifier,It is widely used in engineering plastic materials with strong moisture absorption, such as: PA.PC.PBT.PET.

1. It is widely used in engineering plastic materials with strong moisture absorption, such as: PA.PC.PBT.PET.

2. The double-layer thermal insulation drying barrel adopts a unique lower blowing pipe design and a cyclone exhaust device to improve drying efficiency, and can prevent heat loss and ensure temperature.

3. Equipped with safe and reliable Schneider electronic components and Guangzhou Bangpu LCD screen computer version, precise temperature control, one-key cutting in Chinese and English, easy operation, export standard.

4. Equipped with alarm indicator and fault display on the LCD screen, it is convenient to monitor faults at any time during work and deal with them in time, improving the efficiency of handling emergency situations.

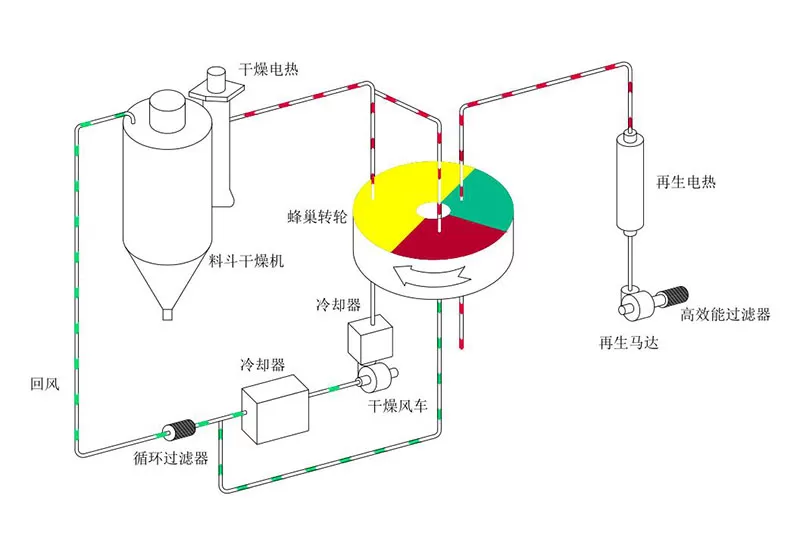

5. The Swedish honeycomb is equipped with imported motor and return air filter to ensure that the honeycomb is not polluted by raw material dust and is more durable.

6. This series of dehumidification system adopts double condenser design to ensure lower return air temperature and dew point.

7. Adopting silica gel adsorption honeycomb dehumidification, the regeneration temperature only needs to be 150℃, which is energy-saving relative to the regeneration temperature of molecular sieve structure above 200℃.

Model | Regenerative heating power(KW) | Regenerative fan power(KW) | Drying electric heating power(KW) | Drying fan power(KW) | Dry air volume | Inlet and outlet pipe diameter(inch) | Dimensions (mm) | Weight(kg) |

MD-30H | 3 | 0.2 | 3 | 0.2 | 30 | 2 | 485*760*1250 | 140 |

MD-50H | 3 | 0.2 | 4 | 0.4 | 50 | 2 | 485*760*1250 | 150 |

MD-80H | 3 | 0.2 | 6 | 0.75 | 80 | 2 | 530*830*1350 | 165 |

MD-130H | 3 | 0.2 | 6 | 1.1 | 130 | 2 | 530*830*1350 | 170 |

MD-160H | 4 | 0.55 | 7.2 | 1.5 | 160 | 2.5 | 660*1060*1550 | 255 |

MD-220H | 4 | 0.55 | 7.2 | 2.2 | 220 | 2.5 | 660*1060*1550 | 260 |

MD-300H | 7.2 | 0.75 | 15 | 3 | 300 | 3 | 700*1260*1750 | 320 |

MD-400H | 7.2 | 0.75 | 18 | 3.8 | 400 | 3 | 700*1260*1750 | 330 |

MD-500H | 10 | 1.5 | 21 | 5.5 | 500 | 4 | 900*1400*1950 | 470 |

MD-700H | 10 | 1.5 | 24 | 7.5 | 700 | 4 | 900*1400*1950 | 480 |

MD-1000H | 15 | 2.2 | 32 | 9 | 1000 | 5 | 1300*1600*2150 | 700 |

MD-1500H | 9*2 | 1.5*2 | 58 | 8.3*2 | 1500 | 6 | 1400*2160*2060 | 1000 |

MD-2000H | 12*2 | 2.2*2 | 75 | 9*2 | 2000 | 8 | 1400*2160*2060 | 1300 |

MD-3000H | 12*3 | 2.2*3 | 96 | 9*3 | 3000 | 8 | 2050*2160*2250 | 1600 |

MD-4000H | 12*4 | 2.2*4 | 125 | 9*4 | 4000 | 12 | 2750*2250*2250 | 2200 |