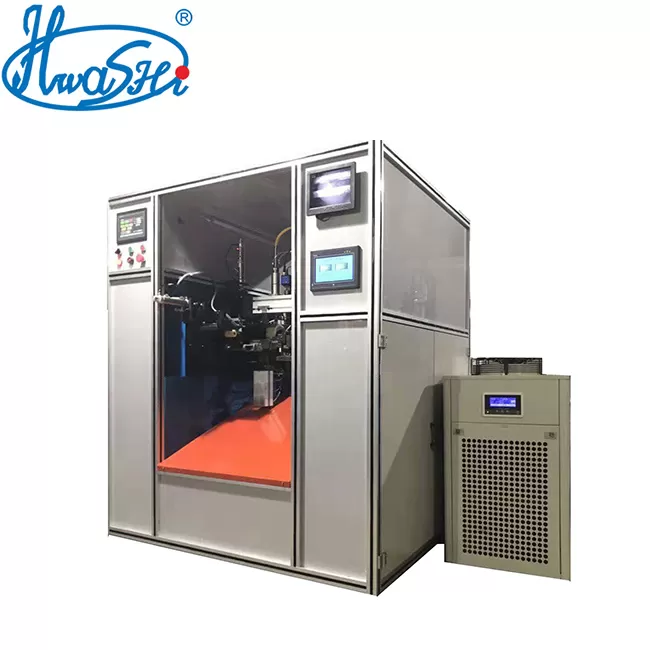

Introduction:Hwashi Lid Steel Belt Automatic Laser Welding Machine

Hwashi Lid Steel Belt Automatic Laser Welding Machine

This machine is of high efficiency and high precision servo motor feeding, high speed pneumatic clamping, cutting, accurate welding, and automatic discharge of products. Achieve automatic production. The high-quality welding seams are gray and white. Nitrogen is needed to protect the smooth and beautiful surface, without burr. The welding fastness can withstand the extension of 5mm, without the need for second time qualitative extension; The loose welding rate is less than 0.1%. The machine will give alarm if there is out of material or jam of material. Low-cost enterprises are currently facing the difficulty of employment. This equipment integrates multiple operation processes, and one worker can operate three welding machines at the same time Dimensions applicable to glass cover: steel strip thickness 0.15mm-- 0.8mm steel strip width 8mm-- 53mm steel strip diameter 100mm-- 300mm.

Advantages of automatic steel belt laser welding machine compared with conventional spot welding machine:

1) Full automatic laser welding machine, the weld surface is beautiful, without burr, no need for grinding and polishing process.

2) The welding efficiency is between 7000 and 9000 pieces per 8 hours. Highly efficient skilled workers can produce anywhere from 3, 000 to 4, 500 pcs a day. Low production efficiency, high welding defect rate.

3) The defect rate of laser welder can be controlled at 0.1%. There are almost no defective products. The artificial defect rate is between 1% and 5%. The wider the diameter of the steel belt, the higher the defect rate.

4) Production cost saving: one worker can operate more than one set of equipment. Only ordinary workers can cooperate. Ordinary equipment should be handled by hand skillfully, and one person can only operate one machine. Workers cost about twice as much as fully automated laser welders.

5) This device needs no polishing. Polishing treatment, polishing cost of each cost of 0.01RMB.

6) The scrap cost is extremely low.

Laser Power | 500W | Total Machine Power | 5KW |

Welding Speed | 14-18pcs/min | Input Voltage | 220V single-phase |

Steel Belt Width | 8-53mm | Nitrogen Protection | Optional |

Steel Belt Thickness | 0.15-0.8mm | Marking Function | Optional |

Steel Belt Diameter | 100-300mm | Cooling Method | Water cooling |

Machine Weight | 1350kg | Machine Dimension | 1480x1280x1680mm |