Flinks: https://www.heatsinksmfg.com

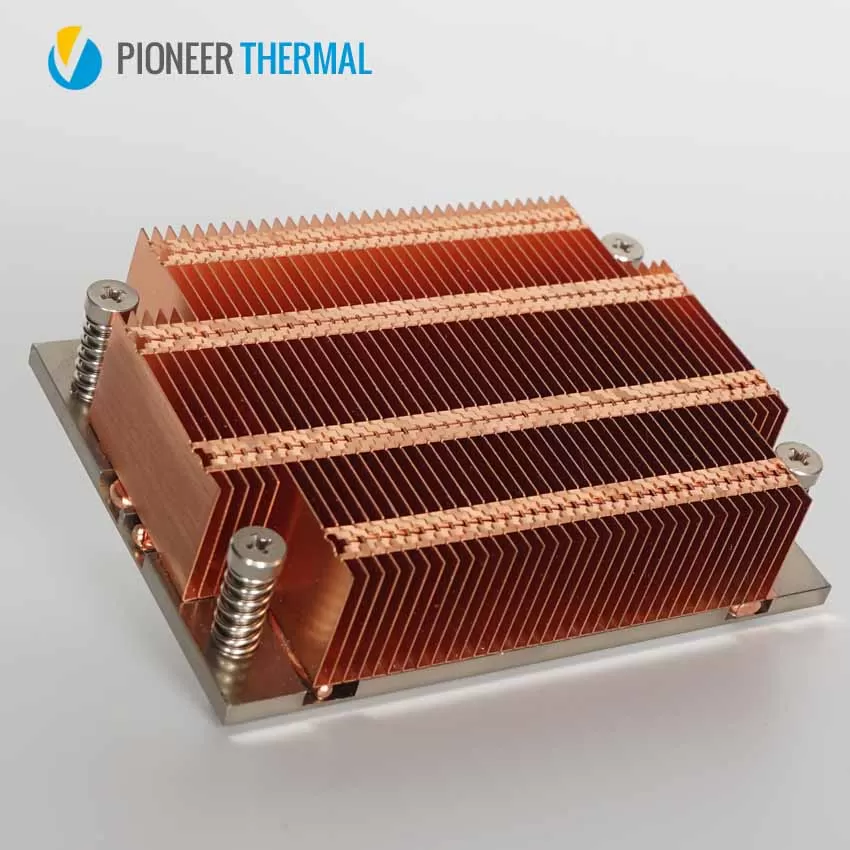

Introduction:Copper Heat sink for Welding

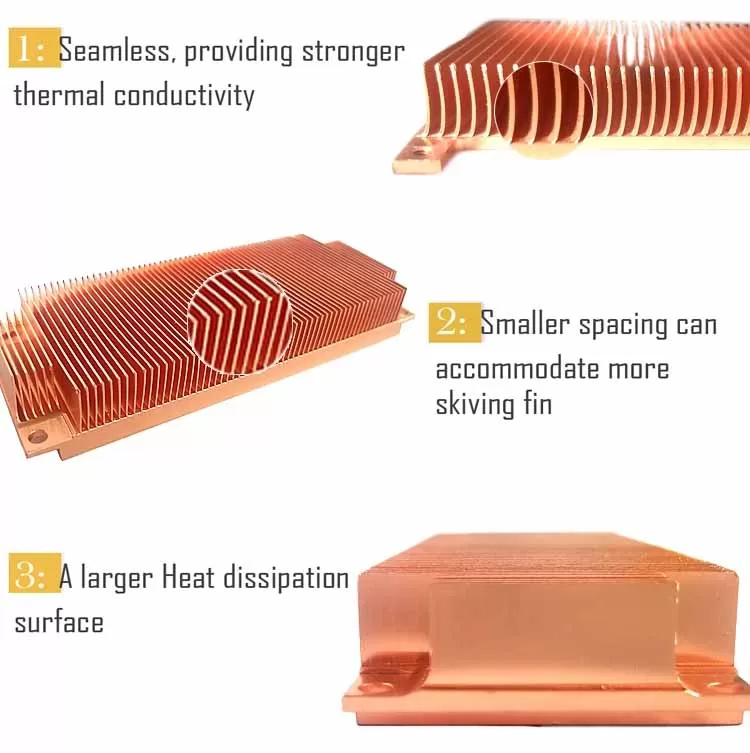

Copper welding heat sink is designed to welding the fins on copper base by environmental protection lead-free medium temperature soldering process.

The fins can be folded fin, L-fin, zipper fin, or fins with heat pipe, and the material is generally AL6063, AL6061, C1100, etc.

According to the material, the welding heat sink can be divided into copper welding heat sink, copper soldering heat sink, copper&aluminum composite soldering heat sink, zipper fin welding heat sink, heat pipe soldering heat sink. According to the process, welding heatsink can be divided into high temperature soldering and low temperature welding. For high temperature welding heatsink need 700-800 degrees to weld. Commonly used welding process is low-temperature soldering, low-temperature welding heat sink temperature between 200-300 degrees, basically no deformation, can be process with high precision processing, can be used with any equipment.

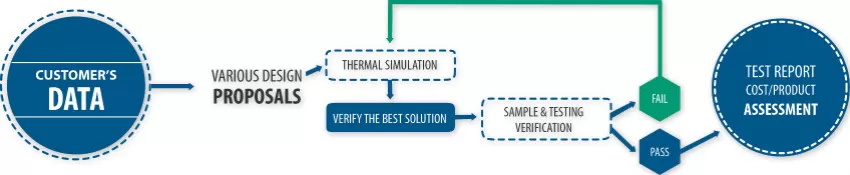

Design Flowchart

Custom Heat pipe Heat sink, Copper heat sink Supplier, heatsink OEM service.

| Place of Origin: | Dongguan, China (Mainland) | OEM: | Yes |

| Process: | Welding | Temper: | T3-T8 |

| Material: | Copper heat pipe+AL6063 | Shape: | Square |

| Packing: | Standard Export Packing | Brand Name: | PIONNER THERMAL |

| Application: | IT equipment and communication equipment | Certificate: | ISO 9001:2015,ISO 14001:2015 |

| Model Number: | PT050 | Tolerance: | 0.01 mm |

| Finish: | Chemical nickel plating | Quality control: | 100% thermal test |

| Extra process: | CNC Machining | Size: | Custom size |