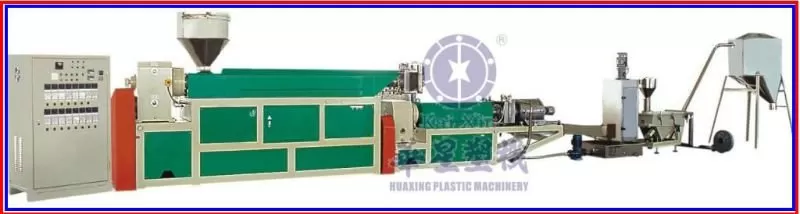

Introduction:PE plastic flakes recycling extruding and pelletizing machine

PE plastic flakes recycling extruding and pelletizing machine

| HXSJ140/140-SR | |

Main extruder | Screw dia | Ø140mm |

| Screw Length | 3600mm |

| Screw L/D | 25:1 |

| No of exhauxing hole | Double |

| Material for screw | 38CrMoAlA, Nitriding treatment. |

| Material for barrel | 40Cr ,Nitriding treatment |

| Gear box | 55# low noise gear box |

| Main Motor | 75kw-4pole |

| Motor control means | Triangle reduction start control |

| Heating zone | 9zone |

| Heating power | 58kw |

| Heating means | Stainless steel and quartz heater |

| Cooling means | Copper tube with circular water |

| Mode of mesh changing | Ø280*280mm double hydraulic screen exchanger |

| Item | HXSJ140/140-SR |

second extruder | Screw dia | Ø140mm |

| Screw Length | 1800mm |

| Screw L/D | 12:1 |

| No of exhauxing hole | Single |

| Material for screw | 40Cr |

| Material for barrel | 40Cr |

| Gear box | 45# Low noise gear box |

| Main Motor | 30kw-4pole |

| Motor control means | Triangle reduction start control |

| Heating zone | 5zone |

| Heating power | 33kw |

| Heating means | Stainless steel and quartz heater |

| Cooling means | Copper tube with circular water |

| Mode of mesh changing | Ø280*280mm double hydraulic screen exchanger |

peripherics | Cutter | Die face cutting(hot cutting) |

| Dewater device | Vertical dewater device,driven power 4kw |

| Storage hopper | Stainless steel square hopper |

| Hydraulic drive system | Double valve hydraulic station, power 4kw |

| Funnel | 800*800 stand funnel |

Total power |

| 208kw |

Out put |

| 220-280kg/h |