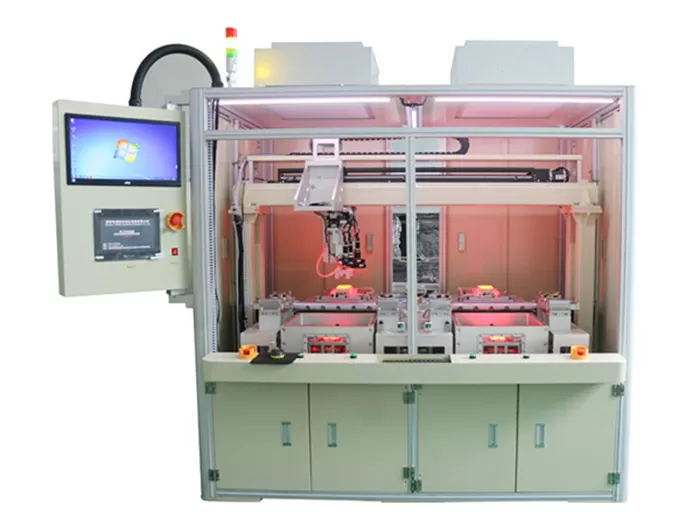

Introduction:Vacuum laminating machine for 3D curved surface

1. Used for bonding the 3D curved glass protective sheet and protective film.

2. Used for bonding the 3D curved glass cover plate and the tear film.

3. Used for bonding the 3D curved cover plate and the OLED.

1. The equipment adopts Japanese SMC pneumatic components and high-precision moving parts.

2. Adopt Japanese Fuji servo and step precision control to ensure the precision of fitting.

3. It adopts Mitsubishi PLC and touch screen control, convenient setting and stable use.

4. Automatic film loading, automatic tear-off film, CCD visual alignment, vacuum attachment and automatic unloading.

| Equipment size (mm) | 2400*1600*2250 | Applicable size | Within 7 inches |

| equipment weight | 2.0T | Counterpoint | CCD visual alignment |

| Equipment power | AC220V /10A 50HZ 9KW (power supply optional) | Fitting accuracy | ±0.1MM |

| working pressure | 0.4~0.6Mpa | Photo thickness | 0.2-0.5MM |

| working environment | 20-40℃ clean, dust-free, clean room | Attaching method | Vacuum attachment |

| Operating temperature | 40%-90% | Productivity | 240-300PCS/H |

| Operation cycle | 12-15S | Program control | Electric circuit control |