Introduction:QD580 is a good performance tool grinding center, suitable for production or repair milling tools, drilling tools, forming tools, etc。

QD580 is a good performance tool grinding center, suitable for production or repair milling tools, drilling tools, forming tools, etc。

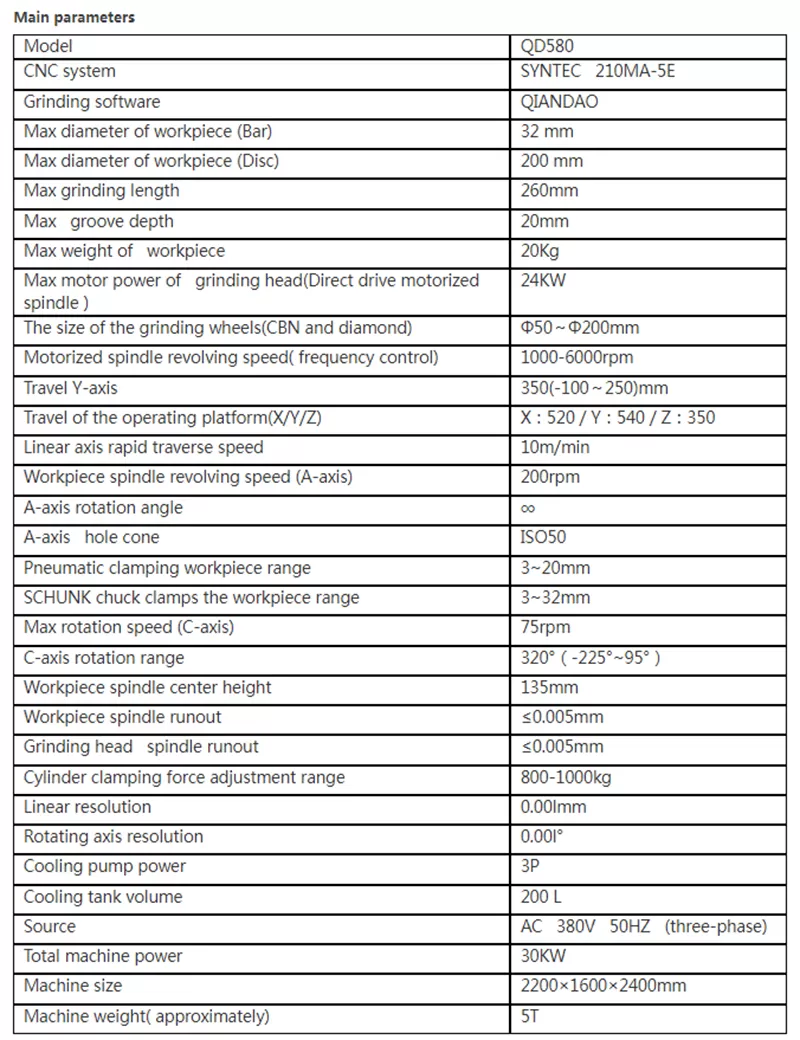

Machine weight:5T

CNC system: the new generation

Machining diameter:200mm (max)

Grinding length:200mm (max)

Processing groove depth:20mm (max)

Machine tool power:28KW

External dimension:2300x1600x2400mm

Product highlight:

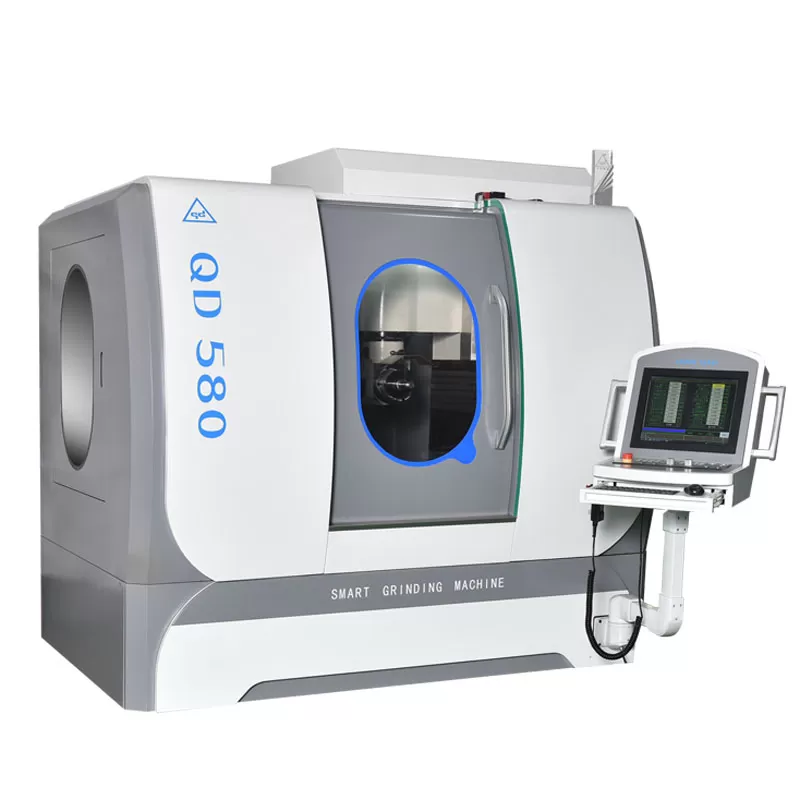

QD580 5-axis CNC tool grinder is a newly developed by Qiandao Machinery, which is a great tool grinding center. It could produce and sharpen all kinds of milling cutters, drilling and forming tools

It looks magnificent and smart and has a much more humanism design, the entire machine operation table can be realized. Machine body is made of natural granite and that has been stable performance in the production.

The spindle grinding head adopts high rigidity, high-precision and with high power (12kw) direct drive frequency conversion. It can be installed with 2-4 pieces of flange grinding wheels. It can satisfy the technical requirement that can one time completes clamping and grinding the front, back and end face of the tool.

The main shaft adopts dd direct drive, bearing is NSK precision spindle bearing, equipped with W25 precision cylinder clamp which matches with Xiao Berlin precision chuck. The workpiece is clamped by pneumatic.

The machine tool is a 210MA-5E 5-axis SYNTEC CNC system and Japanese Igawa Servo Unit. It uses the British Renishaw LP2DD precision probe, silver precision rolling wire rail and ball screw, Hyde Han encoder of Germany. Meanwhile, in order to more ensure the process the precision of the milling tools, the rotating shaft of the machine is controlled by DD direct drive full closed loop, which makes sure that will be superior performance and great precision of the milling tools

The machine is fully enclosed appearance (front movable pull door, right and rear maintenance door) with electronic handwheel, special start and stop button and foot switch, equipped with and automatic cooling system and a coolant filter tank, an automatic lubrication device and a suction interface,an alarm buzzer, electrical box cooling air conditioner, making the operation and maintenance of machine simple and convenient.

Workpiece accuracy

Grinding workpiece round runout ≤0.005mm workpiece surface roughness ≤ ra0.2

Standard:

Main engine of machine, SYNTEC CNC system 210MA-5E and servo unit, domestic probe,12KW precision direct drive grinding head, workpiece pneumatic clamping device, suction interface, grinding wheel blue, automatic lubrication device, standard work, automatic cooling device.

Option:

18KW Direct Drive Motor Spindle, Malek Knife Handle & Clip, Filter System, Special Fixture, Grinding Wheel, Automatic Feeding Device, British Rainesho LP2D Tester, Mapos Tester, etc.