Introduction:TAP110 Gum back AOI equipment

Introduction:

The equipment is equipped with self-developed vision software platform and machine vision detection algorithm, with detection speed up to 12m/min and high detection efficiency. Two sets of circular light + coaxial light are used to pursue lower rate of missed detection and misjudgment. Suitable for the appearance and size detection of all kinds of adhesive parts, mainly foreign body, overflow, lack of glue, fold, plug hole and so on.

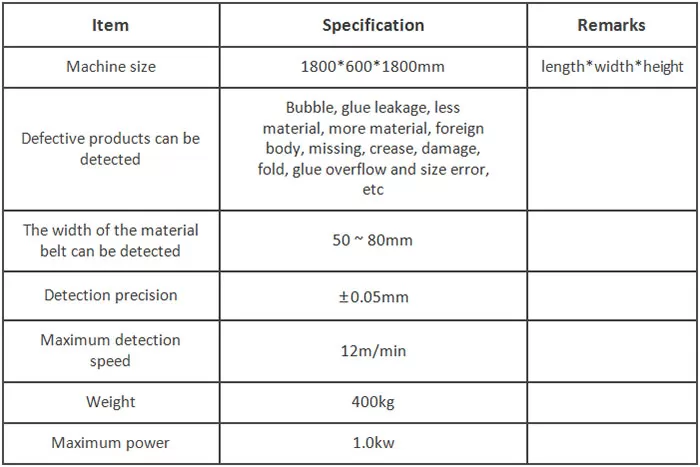

Parameter:

Advantage:

High detection efficiency: the machine is equipped with feeding and receiving plates on the left and right sides to ensure detection efficiency. Detection speed up to 12M/min;

Solution:

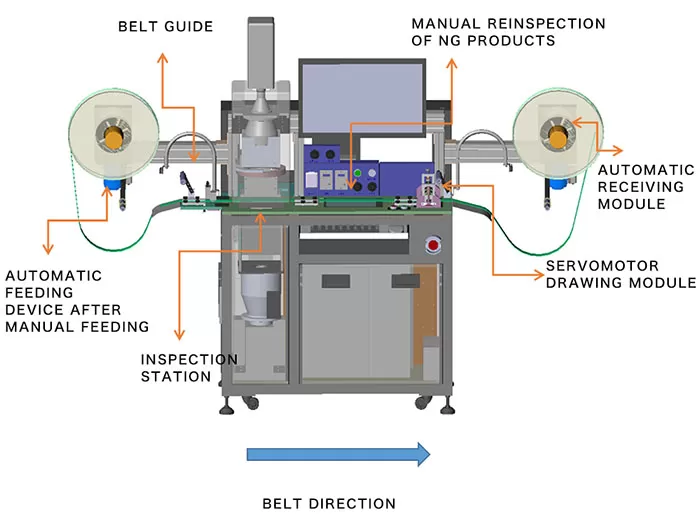

Equipment description: Manually put the material tray to the feeding module after the traction belt through the belt guide module - detection station - manual re-inspection station - drawing module - receiving component, start the equipment, the equipment can automatically feed detection.

After the NG product is found, the NG product is stopped at the reinspection station, and the equipment is started to continue testing after manual processing.