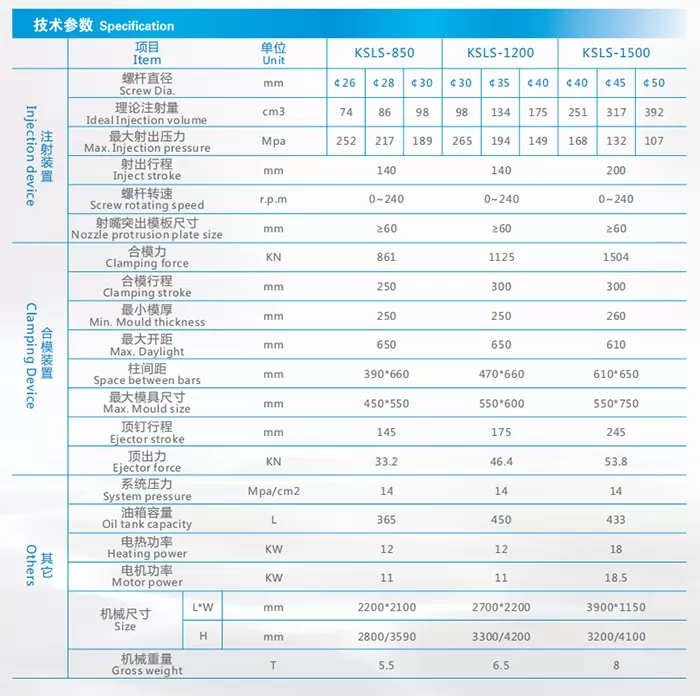

Introduction:Vertical Liquid Silicone Injection Molding Machine KSLS-850 Series

Advantages of liquid injection machine

· Stable quality

The injection machine automatically extracts the raw materials mechanically, measures them at a ratio of 1:1, and accurately injects them into the mold through the screw. This overcomes the problem of unstable quality of the molding press due to man-made production.

· efficient

When using the injection machine to produce, the raw materials do not need to be mixed and color matched; no manual weighing or swinging is required; all are controlled by the machine computer, automatic feeding, metering, high repeatability, double sliding plate continuous action ejection, almost no molding Time, high efficiency and stable quality. One injection machine is equivalent to the production capacity of two vulcanizers.

· save human effort

One machine only needs one operator (male and female), no technical experience is required, as long as the product can be blown out. The injection machine has one person in one-shift system, and two-shift system requires two people, and there is no need for mixing employees. Compared with vulcanizing machine, at least 3 labors can be saved.

· Save raw materials

The product has thin and small burrs, self-dismantling and easy to clean, and the flow channel is small and shallow, which can save raw materials.

· Save power resources

Under the production of the same quantity of products, only 3 sets of electric heating tubes and 1 motor are needed, and it is a servo motor, which saves more power resources.

Machine features

· Direct pressure hydraulic device to ensure accurate mold operation.

· The double lower mold quick sliding mold device is suitable for high efficiency production.

· LSR special pneumatic self-sealing water-cooled closed nozzle to ensure that there will never be leakage.

· The injection system is specially designed according to the characteristics of LSR to ensure more accurate feeding and metering.

Applicable production range

Kitchen supplies, medical supplies, adult supplies, electronic accessories, diving equipment, etc.