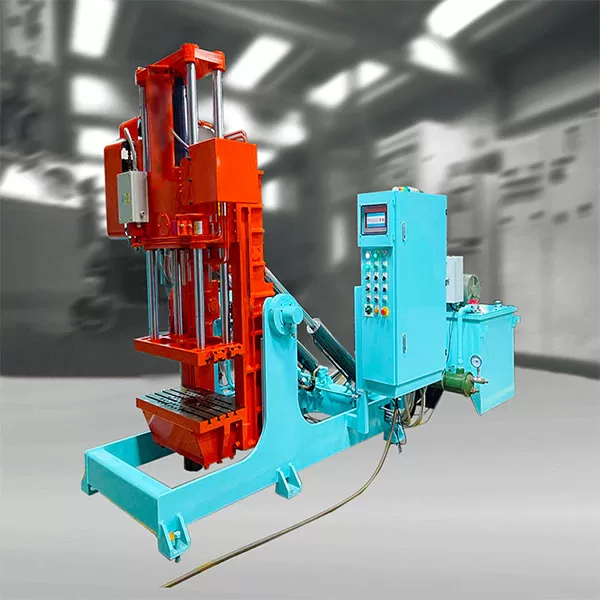

Introduction:Gravity die casting machine PN2B650-80ALD-3.0

Technican parameters

1. Device: PLC control.

2. Operation: hydraulic system transmission, (1 hydraulic main pump system can control 3 pouring machines), hydraulic main pump power of 11KW; equipped with water cooler system, system oil temperature detection, liquid level detection, negative oil pressure detection, and water inlet temperature detection of cooler.(The cooling water source of the external access equipment is supplied by the customer itself).

3. Casting function: 1. Pour into, 2. Fixed, 3. oblique injection, 4. inclined parts, 5. inclined injection.

4. Casting speed 4 section variable speed adjustable: tilt casting Angle from 0-90 degrees at any Angle.

5. Angle: horizontal 0 degrees, tilt 90 degrees, two choices; upper module.

(When the mode is opened, the lower module starts the top out synchronously, and brings the workpiece to the upper module again).

6. Mold cooling and heating.

7. Size of mold fixed seat: 800 * 400 * 60mm, (with 5 groove of pressing plate groove).

8. Maximum mold weight: 800kg (at 0-85 degrees).

9. Maximum mold stroke: 450mm.

10. Maximum spacing between both sides of the mold fixed plate: 750mm.

11. Minimum spacing between both sides of the mold fixing plate: 300mm.

12. Neutron (core pumping): there are four ways that can work independently or in sequence or simultaneously, (the oil cylinder connected to the mold is supplied by the customer himself).

13. Curing time: Adjustable.

14. Casting process time can be displayed.

15. The mold temperature can be set at the upper and lower limits. When the mold temperature exceeds the upper and lower limits, the mold can not be closed for the next cycle action, or the optional action can not be controlled by the mold temperature.

16. There is a die-water cooling pipe device system.

17. Net weight of the equipment: about 4,500 k g.

18. Machine specification: 2996mm * 1805mm * 2150mm (use space).(Equipment height is 3071mm when the workbench is rotated to 90 degrees).

19.The pouring speed can be divided into 4 sections