Introduction:Universal Testing Machine RS-8010W-5KN

Model:RS-8010W-5KN

This UTM are suitable for the testing of tension, compression, shearing force, adhesion, peeling force, tear strength etc for semi-product & finished product in the field of rubber, plastic, metal, nylon, fabric, paper, aviation, packing, architecture, petrochemistry, electric appliance, automobile, etc, which are the basic facilities for input quality control(I.Q.C), Quality Control(Q.C.), physical inspection, Mechanics research and material development.

| Capacity(optional) | 5kgf, 10kgf, 20kgf, 50kgf, 100kgf, 200kgf, 500kgf |

| Unit(switchable) | N, KN, Kgf, Lbf |

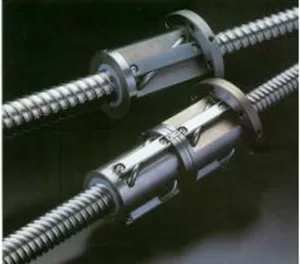

| Dynamic system | Panasonic®AC servo motor+ Motovario® gear reducer+ Mitsubishi®synchronous belt + TBI®BALL screw |

| Load cell accuracy | ±0.03%F.S |

| Load resolution | 1/500,000 |

| Level of the accuracy | ±0.25% |

| Measurement accuracy | ±0.25%F.S |

| Effectiverange | 1%~100%F.S |

| Stroke resolution | 0.001mm |

| Stroke measurement accuracy | Less than ±0.5% of the display |

| Deformation resolution | 0.001mm |

| Deformation measurement accuracy | Less than ±0.5% of the display |

| Stroke(exclude the grips) | 250mm |

| Effective width | 200mm |

| Test speed | 0.1~500mm/min |

| Speed accuracy | ±0.5% |

| Deformation measurement(purchasing additional) | large deformation:10~1000mm, Electronic extensometer: gauge length-25mm, deformation-25mm |

| Fixtrue | Tension, compression |

| Limiting protection | Mechanical lim it'structure |

| Overload protection | Over maximum load 10%, machine protection |

| Computer | DELL |

| Main unit dimensiom(WxDxH) | W1150xD450xH500mm |

| Main unit weight | 105kg |

| Power | AC 220V 3A |

| Noise | 5mm/min 60dB(A) 500mm/min 68dB(A) |

Meeting Standards

The tester is based on the electronic universal testing machine-GB/T 16491-2008, the testing machine general technical requirements-GB2611-2007, the tension and compression testing machine test system testing, the extensometer technical conditions- JB6146-2007, the manufacturing measuring instruments permit examination general specification standard manufacturing JJF1246-2010.

GB/T228-2002、GB/T14552-93、ASTMD638-03、ASTMD790-07;

GB/T2792、ASTM D3330-04 Standard test method for peel adhesion of pressure-sensitive tape(Test Method A-Single-Coated Tapes at 180° Angle).

ASTM D1894-06 Standard test method for static and kinetic coefficients of friction of plastic film and sheetiing (single coated tapes at 90° angle).

Adopt AC servo motor to driving the high precise ball screw working, with high precise explosion- proof load cell, load accuracy reached to ±0.25% & displacement accuracy reach to 0.001mm.

Automatic broken identification, automatically return, point collected by hand, multi-units switching.

Professional version satisfies the low cycle test, realizes the closed-loop control of force, speed, displacement and so on, it can be programmed and tested according to the test needs; according to the test needs, force rate, deformation test, retaining force test, cyclic test and so on; meets the durability test of materials. The standard version does the general force test by setting the speed. All tests can record and memorize the whole test data. At the same time, it can display a variety of analytical curves: stress and strain curves, load and bending curves, strength and deformation curves, strength and time curves, time and bending curves.

●Multi-function

Can coordinate with different grips, the tests of tension, compression, bending, shearing, tearing, peeling, elongation rate etc can be done.